Serpentine Belt Noise: Causes, Fixes & When to Worry

Advertisements

- January 2, 2026

Quick Guide

- What Does Serpentine Belt Noise Actually Sound Like?

- So, What's Causing All This Racket?

- How to Diagnose Serpentine Belt Noise Yourself (The Safe Way)

- DIY Fix vs. Calling a Pro: What Makes Sense?

- Can You Drive With a Noisy Serpentine Belt?

- Keeping the Quiet: Prevention and Maintenance

- Your Serpentine Belt Noise Questions, Answered

Okay, let's be real for a second. You're sitting in your car, maybe at a red light or just starting it up in the morning, and there it is. A sound that wasn't there yesterday. A high-pitched squeal that makes you cringe, or maybe a rhythmic chirping that taps out an annoying beat under the hood. Your first thought might be, "Is this serious? Can I keep driving?" and your second is probably, "How much is this going to cost me?"

Chances are, you're hearing a classic case of serpentine belt noise. It's one of the most common car sounds out there, and honestly, it's also one of the most misunderstood. Some folks panic, thinking the engine's about to blow. Others ignore it until their car overheats on the highway. I've seen both happen.

I remember the first time I heard that squeal on my old truck. I was sure it was something terminal. Turned out, it was just a worn belt and a loose tensioner—a fix that cost me less than a tank of gas once I figured it out. That experience is why I'm writing this. I want to cut through the confusion and give you the straight story on serpentine belt noise.

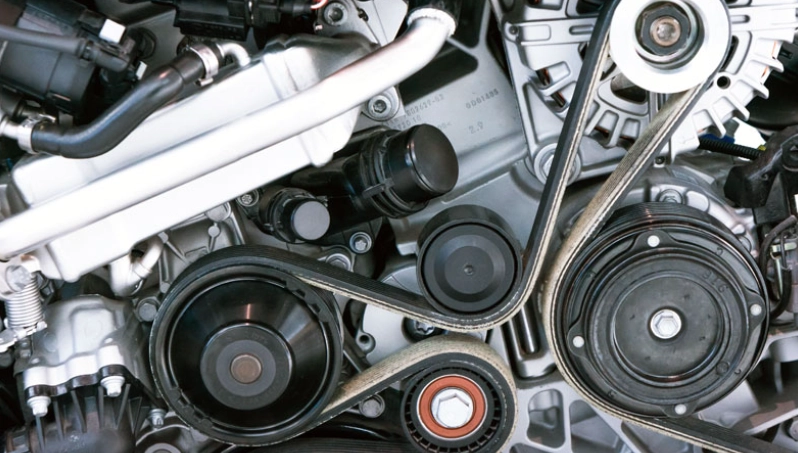

Quick Reality Check: The serpentine belt (sometimes called the drive belt or accessory belt) is that long, snaking rubber belt you see at the front of your engine. Its one job is incredibly important: it spins the alternator, power steering pump, water pump, and air conditioning compressor. No belt, no charge for your battery. No belt, no coolant circulation. You get the idea.

What Does Serpentine Belt Noise Actually Sound Like?

Not all noises are created equal. The sound your belt makes is like a symptom telling you what's wrong. Misdiagnosing it is easy, so let's break down the common ones.

The infamous squeal. This is the poster child for serpentine belt noise. It's usually a loud, high-pitched shriek, most common when you first start a cold engine or when you turn on a heavy electrical load like the A/C or headlights. Why? It's almost always about grip—or the lack of it. The belt is slipping on one of the pulleys. Think of a sneaker squeaking on a gym floor.

Then there's the chirp or squeak. This is more rhythmic, often one chirp per revolution of the belt. It's a sharper, shorter sound than the sustained squeal. This little devil is frequently caused by a misalignment. One of the pulleys isn't sitting perfectly straight, so the belt edge rubs and chirps as it goes by. It can also mean a hardened spot on the belt or a bad bearing starting to fail in one of the components.

A slapping or flapping sound is less about pitch and more about... well, flapping. It sounds like something loose is whipping around. This is a dead giveaway for a severely worn or damaged belt. You might have a chunk missing, deep cracks (we call them dry rot), or the belt might have become glazed and slick. The belt isn't tracking smoothly anymore; it's literally slapping against the engine covers.

And sometimes, you get a low growl or rumble. This one's tricky because it often points away from the belt itself and toward a failing bearing in one of the components the belt spins, like the idler pulley, tensioner pulley, or the alternator. The belt is just transmitting the sound.

So, What's Causing All This Racket?

Pinpointing the exact cause saves you time and money. You don't want to replace a perfectly good belt only to find the noise is still there because the real culprit was a $15 idler pulley.

Here are the main suspects, in my experience from most to least common:

A Worn-Out or Damaged Belt

This is the obvious one. Rubber doesn't last forever. Heat, ozone, and constant flexing break it down. Look for:

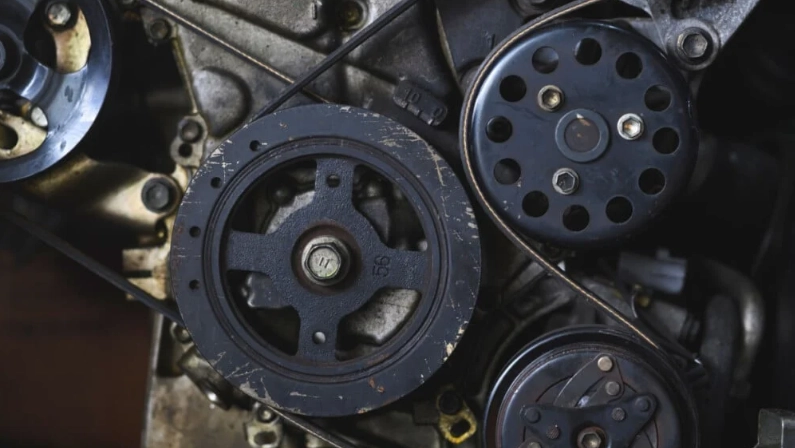

- Cracks (Dry Rot): Small hairline cracks on the ribbed side are normal with age. But if you see deep cracks where you can almost see the underlying cords, that belt is toast. It's lost its flexibility and grip.

- Glazing: The ribs on the belt look shiny and smooth, like they've been polished. This happens from prolonged slipping. A glazed belt has lost its friction and will squeal.

- Missing Chunks or Ribs: Physical damage. Maybe a piece of debris got in there, or the belt was installed incorrectly. This causes vibration and slapping noises.

Problems with the Belt Tensioner

This is the unsung hero (or villain) of the serpentine belt system. Its job is to keep the belt tight. Over time, the spring inside weakens, or the pivot wears out. A weak tensioner allows the belt to be too loose, leading to slippage and squealing. A seized tensioner pulley bearing will cause a growl or chirp. This part fails way more often than people think.

Watch Out: An automatic tensioner under heavy spring pressure can be dangerous if you don't know how to handle it. If you're poking around, never put your fingers between the belt and a pulley when the engine is even remotely possible to start. A simple wrench slip can lead to serious injury.

Contamination: The Silent Killer

Oil, coolant, or power steering fluid leaking onto the belt is a death sentence for it. Rubber and oil don't mix. The fluid soaks into the belt, causing it to swell, soften, and lose all its gripping power. You'll get immediate, severe squealing. If you have a serpentine belt noise and see wet, shiny patches on the belt or pulleys, you've found your problem—and you have a separate leak to fix, too.

Misaligned or Worn Pulleys

Every pulley the belt runs on needs to be perfectly aligned. If an idler pulley bracket gets bent, or a component like the power steering pump starts to shift on its mounts, the belt will run at an angle. This wears the edge of the belt fast and creates that rhythmic chirping noise. Also, pulleys can get grooves worn into them from an old belt, and a new belt might not seat properly.

Failing Component Bearings

Remember, the belt is just the messenger. If the bearing inside the alternator, water pump, or an idler pulley is starting to fail, it will make noise. The belt, being tightly connected, transmits that grinding or rumbling sound. This is why the "screwdriver stethoscope" trick is so useful—it helps isolate which component is singing the sad song.

How to Diagnose Serpentine Belt Noise Yourself (The Safe Way)

You don't need to be a master mechanic to get a good idea of what's wrong. Here's a step-by-step process I use. Do this when the engine is COMPLETELY COLD.

Step 1: The Visual Inspection. Pop the hood. Find the belt (consult your owner's manual if needed). Look it over inch by inch. Are there deep cracks? Is it shiny? Is it missing bits? Check the tensioner—does it look rusty or seized? Look for signs of fluid leaks on or near the belt path.

A quick glance can tell you a lot.

Step 2: The "Cold Start" Test. This is the best way to catch a slipping belt. First, make sure the car is in Park (or Neutral with the parking brake on) and clear of anything. Start the engine first thing in the morning. Listen closely. A loud squeal that lasts 2-3 seconds then fades is classic belt slip on a cold, damp morning. If it squeals constantly, the problem is more severe.

Step 3: The "Load" Test. With the engine warmed up and idling in Park, turn on every electrical accessory you can: high-beam headlights, rear defroster, fan on high, and most importantly, the A/C. Listen for a squeal that appears or gets worse. This puts maximum load on the alternator and A/C compressor, stressing a weak belt or tensioner.

Step 4: The Tension Check (Carefully!). Find the longest, straightest run of the belt between two pulleys. Press down on the middle of that run with moderate thumb pressure. How far does it deflect? A general rule is about 1/2 inch of play. If you can push it down an inch or more, it's way too loose. If it's rock solid, the tensioner might be over-tightening (less common). Your car's service manual has the exact spec—organizations like the SAE International set these engineering standards, and mechanics rely on them.

Pro Tip from the Garage: A little trick I learned is to put a few drops of water on the *smooth backside* of the belt while the engine is running. If the noise stops for a few seconds, you've confirmed it's a belt slippage issue (the water provides temporary grip). If the noise doesn't change, the problem is likely a bearing or pulley alignment issue. Just use water, not any other liquid!

DIY Fix vs. Calling a Pro: What Makes Sense?

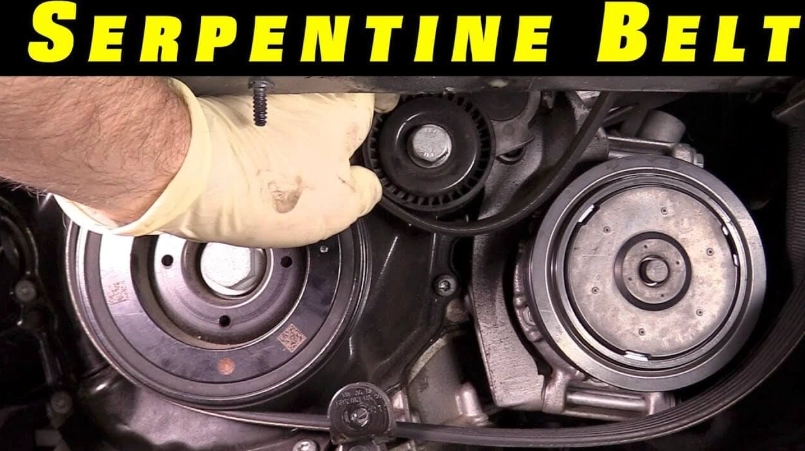

Replacing a serpentine belt is often considered a beginner to intermediate DIY job. But it's not always straightforward. Let's weigh it.

You can probably handle it yourself if: Your car has a simple, easy-to-access routing path. You have a basic socket/wrench set and the right size breaker bar or long-handled ratchet to move the tensioner. You're comfortable following a diagram (the routing is usually on a sticker in the engine bay or in the manual). You've confirmed it's just the belt that's bad.

You should seriously consider a pro if: The routing is insanely complicated (some transverse V6 engines are nightmares). You need to remove other components just to access the belt. The tensioner is in a terrible spot. You suspect the tensioner or an idler pulley is also bad. You have an oil leak that needs fixing first. You just don't feel confident—there's no shame in that.

The cost difference is real. A quality belt might cost you $25-$60. A tensioner assembly another $50-$150. Doing it yourself, you're just out parts. At a shop, you're looking at 0.5 to 1.5 hours of labor on top of parts. I've seen total bills range from $120 for a simple belt swap to over $400 if they replace the belt, tensioner, and an idler pulley.

| Potential Issue | DIY Fix Complexity | Estimated Parts Cost | Likely Shop Cost (Parts & Labor) |

|---|---|---|---|

| Serpentine Belt Replacement Only | Low to Medium | $25 - $60 | $120 - $200 |

| Belt + Tensioner Assembly | Medium | $75 - $200 | $200 - $350 |

| Belt + Tensioner + Idler Pulley | Medium to High | $100 - $250 | $250 - $450+ |

| Belt + Fix Underlying Fluid Leak | High (varies greatly) | Varies Widely | Can add $150-$500+ |

Can You Drive With a Noisy Serpentine Belt?

This is the million-dollar question, right?

Here's my blunt take: It depends on the noise and for how long, but you are always driving on borrowed time. That serpentine belt noise is a warning, not background music.

If it's a mild, occasional chirp when cold, you likely have a little time to schedule a repair. But I wouldn't plan a cross-country road trip.

If it's a loud, constant squeal or a slapping sound, you're in the danger zone. A belt that's slipping badly isn't spinning the water pump effectively, risking overheating. It's not spinning the alternator properly, which can drain your battery and leave you stranded. A belt that snaps will cause immediate loss of power steering (making the wheel very hard to turn) and the battery warning light will come on as the alternator stops. Your engine will start to overheat within minutes as the water pump stops.

I had a friend ignore a squeal for two weeks. He made it to work and back, thinking it was just an annoyance. Then the belt snapped on the freeway. The tow and repair bill was much higher than if he'd just replaced the $40 belt when he first heard the serpentine belt noise. Not a fun lesson to learn.

Red Flag Stop Driving Scenarios: If the noise is accompanied by a battery warning light, temperature gauge climbing, or you see smoke/smell burning rubber, pull over safely as soon as possible and shut the engine off. Continuing to drive risks catastrophic engine damage from overheating.

Keeping the Quiet: Prevention and Maintenance

The best fix is the one you never have to do. Serpentine belts don't need much, but a little attention goes a long way.

First, know the replacement interval. The old rule was every 60,000 miles. Modern belts last longer—often 90,000 to 100,000 miles or more. But don't just go by mileage. Time is a factor too. A 10-year-old car with 50,000 miles can have a belt rotten with dry rot. Check your owner's manual for the manufacturer's recommendation. It's the bible for your specific car.

Make visual checks part of your routine. Every time you check your oil or wash the car, take 30 seconds to glance at the belt. Look for cracks, glazing, and fraying. It's that simple.

Listen. This sounds obvious, but pay attention to new sounds. That first little chirp is your cue to start investigating.

Fix leaks promptly. If you see an oil leak from the valve cover or elsewhere dripping down, get it fixed before it ruins the new belt you just installed.

When you do replace the belt, consider replacing the tensioner and idler pulleys at the same time, especially if the car has high mileage. It's cheap insurance. The labor is already being done, and a new belt on old, worn pulleys can lead to premature failure and a return of that serpentine belt noise sooner than you'd like.

Your Serpentine Belt Noise Questions, Answered

The bottom line is this: Your car is talking to you. That serpentine belt noise is it saying, "Hey, something in my accessory drive needs attention." Ignoring it is a gamble, and the stakes are a tow truck and a much bigger repair bill. Listen to it, diagnose it simply, and deal with it promptly. Your wallet—and your peace of mind on the road—will thank you.

Leave A Comment