The Right Solder for Radiator Repair: A Complete DIY Guide

Advertisements

- January 26, 2026

Quick Navigation

- Why Your Regular Solder Probably Won't Work

- Breaking Down the Solder Types: What Actually Works

- The Tool Checklist: What You Really Need

- The Step-by-Step Process: From Leak to Fixed

- Common Pitfalls and How to Avoid Them

- Answering Your Burning Questions (FAQ)

- Final Thoughts: Empowerment Through the Right Knowledge

Let's be real for a second. A leaky radiator, whether it's the one keeping your house warm in winter or the one preventing your car's engine from melting, is a massive headache. You see that little drip, that faint stain of coolant or water, and a sense of dread sets in. A professional repair can cost a pretty penny, so naturally, the DIY spirit kicks in. You grab your torch, you find some old solder wire in the garage, and you think, "How hard can it be?"

I've been there. I once tried to fix a small pin-hole leak on an old home radiator with generic electrical solder. It was a disaster. The solder just beaded up and rolled off like water on a hot plate. It didn't stick at all. I was confused, frustrated, and left with a still-leaking radiator and a bruised ego. That failure sent me down a rabbit hole of research, and what I learned completely changed my approach. It all comes down to using the right solder for radiator repair.

This isn't just about sticking metal together. It's about creating a bond that can withstand constant heating and cooling, internal pressure, and the corrosive nature of coolant or water. Using the wrong materials is the #1 reason DIY radiator fixes fail. So, let's ditch the frustration and get you equipped with the knowledge to do it right the first time. This guide is everything I wish I had known before I started.

Why Your Regular Solder Probably Won't Work

First things first, we need to clear up a huge point of confusion. Not all solder is created equal. The solder you use for a copper pipe or for circuit boards is formulated for those specific jobs. Radiators present a unique set of challenges.

Think about what a radiator does. It gets hot, then it cools down. It holds liquid under some pressure. The liquid inside (water or antifreeze) can be slightly acidic. This constant thermal cycling and chemical environment is tough on any joint.

Standard lead-free plumbing solder (like 95/5 Tin-Antimony) or acid-core solder from a hardware store often lacks the strength and fatigue resistance for this job. It might hold for a while, but as the metal expands and contracts thousands of times, the joint can crack. That's why a dedicated solder for radiator repair is formulated differently. It's designed to be stronger and more flexible to handle that stress.

And then there's the metal itself. Old radiators can be coated in layers of paint, rust, and mineral deposits. You can't just solder over grime. The surface must be impeccably clean, down to bare, shiny metal. This is non-negotiable. I learned this the hard way—no amount of good solder can overcome a dirty surface.

Breaking Down the Solder Types: What Actually Works

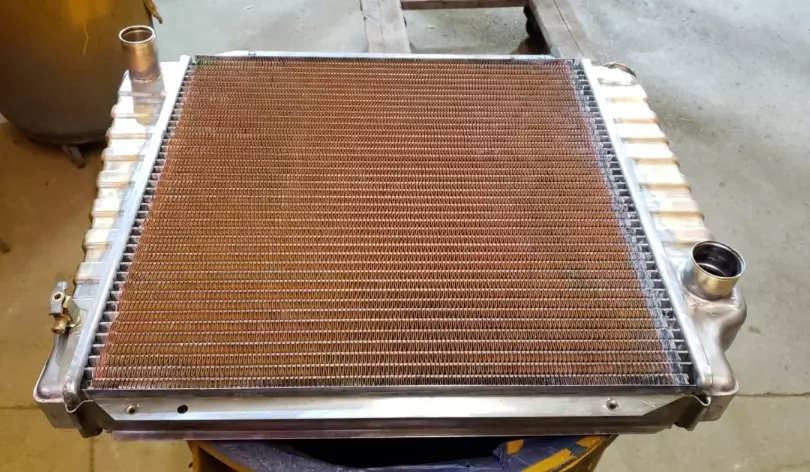

Alright, let's get into the nuts and bolts. When you're looking for solder to fix a radiator, you're primarily dealing with two categories: soft solder and silver solder (sometimes called braze). The choice depends on the size of the leak, the type of radiator, and your skill level.

Soft Solder: The DIY Favorite

This is what most folks think of when they hear "solder." It melts at lower temperatures (typically between 360°F and 460°F / 182°C - 238°C), which is easier to manage with a basic propane torch. For most small to medium pinhole leaks in copper or brass radiators, a high-quality soft solder is perfect.

The magic isn't just in the solder wire, though. It's in the flux. Flux is a chemical cleaner that prepares the metal surface, prevents oxidation during heating, and allows the molten solder to flow smoothly and bond. For radiator work, you need an aggressive, acidic flux. Tinning flux is a fantastic choice because it contains powdered solder, which helps "tin" the surface (coat it with a thin layer of solder) before you make the final joint. This makes the whole process much more forgiving.

A top-tier combination is a solid core solder used alongside a separate paste flux. Brands like Oatey or La-Co make fluxes specifically for metals like brass and copper. Don't skimp on the flux. A $5 tub of the right stuff is worth more than a $20 roll of the wrong solder.

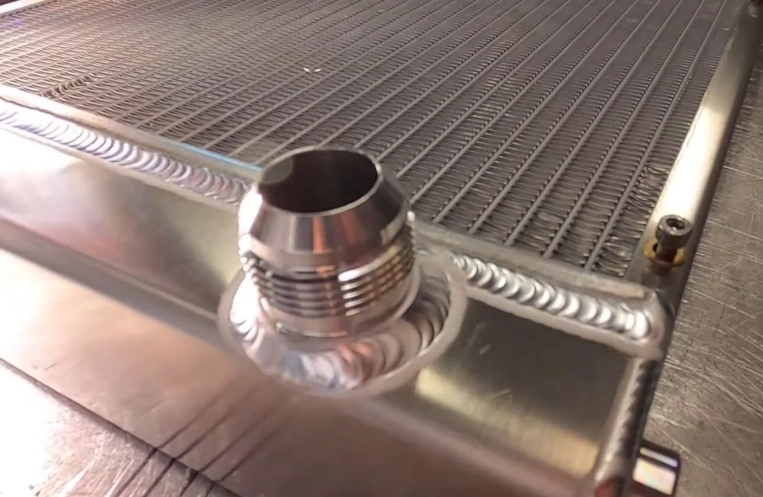

Silver Solder (Brazing): For High-Stress Jobs

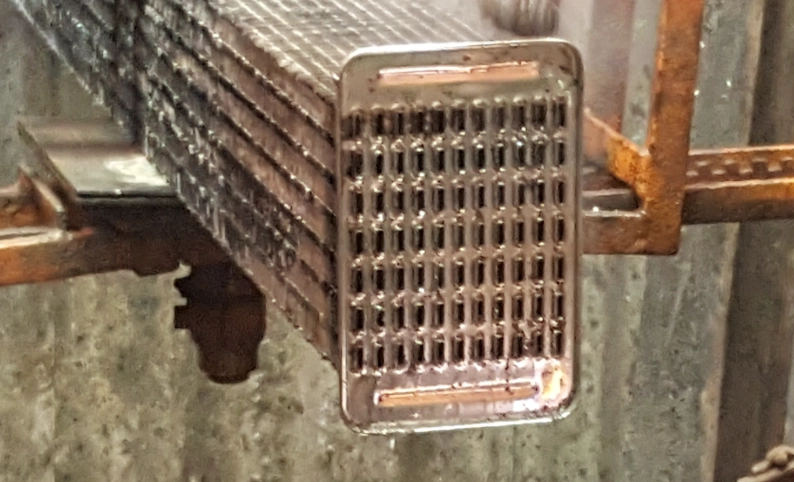

Now, if you're dealing with a car radiator (especially aluminum cores, which are a whole different beast), a large crack, or a high-pressure steam radiator, soft solder might not be strong enough. This is where silver solder comes in.

Silver solder has a much higher melting point (over 1100°F / 600°C) and creates a joint that's often stronger than the base metals themselves. It's essentially brazing. This requires a hotter torch, like MAP-Pro or oxy-acetylene, and more skill to avoid melting the thin radiator fins.

For aluminum radiators, the process is even more specialized. You need a specific aluminum brazing rod and flux. It's tricky, and many DIYers opt for a professional repair or radiator replacement for aluminum. Honestly, unless you've practiced on scrap, I'd be cautious about jumping into aluminum repair.

Here’s a quick comparison to help you decide:

| Solder Type | Best For | Melting Temp | Strength | Skill Level |

|---|---|---|---|---|

| Soft Solder (95/5 Tin-Antimony) | Pinhole leaks in copper/brass home radiators, low-pressure systems | ~450°F (232°C) | Good | Beginner to Intermediate |

| Silver Bearing Solder (e.g., 4% Silver) | Stronger joints for brass/copper, better fatigue resistance | ~430°F (221°C) | Very Good | |

| Silver Solder (Brazing Alloy) | Cracks, high-pressure joints, some automotive applications (non-aluminum) | >1100°F (600°C) | Excellent | Advanced |

| Aluminum Brazing Rods | Aluminum car radiators (specific rods required) | ~700°F (370°C) | Excellent |

See the gap there for aluminum? It's in a league of its own. For the classic cast iron or copper/brass home radiator, a good soft solder is your best bet.

The Tool Checklist: What You Really Need

You've got your solder. Now what else? Having the right tools turns a struggle into a smooth operation. Here’s my tried-and-true list, built from forgetting things and having to run back to the store mid-job.

- Heat Source: A basic propane torch from the hardware store is sufficient for soft solder. Get one with a pencil flame tip for better control. For silver solder, you'll need hotter fuel like MAP-Pro gas.

- Safety Gear: This is non-negotiable. Heavy leather gloves (not cloth), safety glasses with side shields, and long sleeves. Molten solder and hot metal hurt.

- Surface Prep Tools: A wire brush (brass is great), sandpaper or emery cloth (120-grit works well), and a file. You need to get down to bright, clean metal in a area larger than the leak itself.

- Application Tools: Cheap acid brushes for applying flux, and a damp rag or sponge (not the kitchen sponge!) for wiping the joint after soldering. A pair of needle-nose pliers can be handy for holding small pieces.

- Leak Detector (Optional but Smart): After the repair, you need to test it. For home radiators, refill with water and look closely. For car radiators, a pressure tester (you can often rent these) is the professional way to go. The U.S. Environmental Protection Agency discusses proper handling of motor vehicle AC systems, and the principle of pressure testing for leaks is similar and critical for a reliable repair.

The Step-by-Step Process: From Leak to Fixed

Okay, let's walk through the actual repair. I'll focus on the most common scenario: a pinhole leak in a copper/brass home radiator using soft solder. This process is your blueprint.

Step 1: Preparation is 90% of the Job

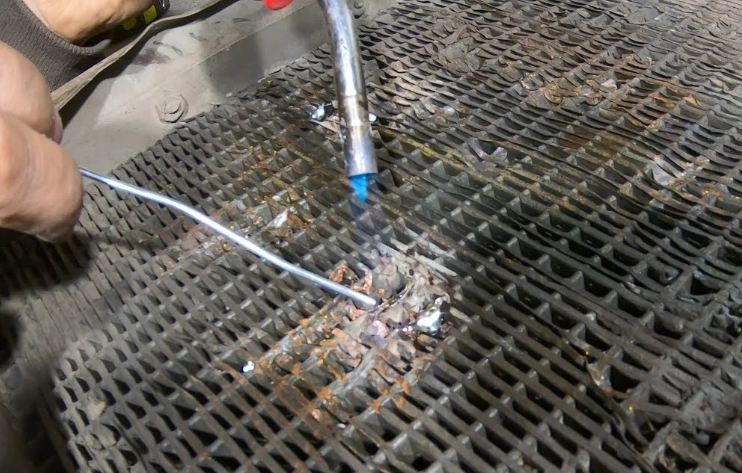

Drain the radiator completely. Let it dry. Then, attack the area around the leak with your wire brush, sandpaper, and file. You need to remove all paint, rust, and oxidation until the metal is shiny and clean. I can't stress this enough—this step makes or breaks the repair. If the metal isn't bright, stop and clean more.

Step 2: Applying the Flux

Using your acid brush, coat the cleaned area generously with your tinning paste flux. Don't be shy. The flux should cover the leak and a good half-inch around it. This flux will bubble and clean the surface as it heats.

Step 3: Heating and Tinning

Fire up your torch. Use a gentle, sweeping motion to heat the metal around the leak, not directly on the hole itself. You want to heat the area so it's hot enough to melt the solder when you touch it to the metal—not the flame. Touch your solder for radiator repair wire to the heated area. If it's hot enough, the flux will sizzle and the solder will melt and flow smoothly, coating the area in a thin, shiny layer. This is called "tinning." If the solder balls up, it means the metal isn't clean enough or hot enough. Stop, let it cool, clean it again, and retry.

This tinning step is the secret to a strong bond.

Step 4: Building the Patch

Once the area is tinned, you can add more solder to build up a small patch over the leak. Continue applying heat to the base metal and feed the solder in. Let it flow and create a small, smooth mound that covers the hole completely. Don't glob it on; a smooth, integrated patch is stronger than a big blob.

Step 5: Cooling and Cleanup

Turn off the torch and let the joint cool naturally. Don't quench it with water, as this can cause stress cracks. Once it's cool to the touch, wipe away any residual flux with a damp rag. Leftover flux can be corrosive over time.

Step 6: The Moment of Truth – Pressure Testing

Refill the system with water. For a home radiator, open the valves and watch your repair closely for any seepage. Look for the smallest droplet. For a car radiator, using a pressure tester is the best practice. Pump it up to the system's rated pressure (usually on the radiator cap) and hold it for 10-15 minutes. If the needle doesn't drop, you've succeeded.

Common Pitfalls and How to Avoid Them

Even with the right solder for radiator repair, things can go sideways. Here are the problems I've either caused or seen others struggle with.

- The Solder Won't Stick (The Biggest Issue): 99% of the time, this is inadequate cleaning. Go back to Step 1. The other 1% is not enough heat. You're heating the solder with the torch, not the metal. Heat the radiator metal until it's hot enough to melt the solder on contact.

- Overheating and Melting the Radiator: Especially with thin fins on car radiators. Use a lower flame and keep the torch moving. Patience is key. If you see the metal start to glow dull red, you're way too hot for soft solder.

- Using the Wrong Flux: Rosin-core flux (for electronics) or mild plumbing flux won't cut it. You need an aggressive, acid-based paste flux for this job.

- Not Draining the Radiator Fully: Even a tiny amount of residual water will boil, create steam, and prevent the solder from bonding. It will also spit hot water at you. Ensure the system is completely dry.

Answering Your Burning Questions (FAQ)

I get a lot of questions from friends and readers about this topic. Here are the most common ones, straight from the inbox.

Final Thoughts: Empowerment Through the Right Knowledge

Fixing a radiator with solder isn't black magic. It's a straightforward mechanical skill that hinges on understanding a few key principles: cleanliness, heat control, and material selection. My initial failure was simply because I didn't respect those principles.

By choosing a high-quality, appropriate solder for radiator repair—paired with the right aggressive flux—and following a meticulous preparation process, you can achieve a professional-grade fix that saves you hundreds of dollars. It's incredibly satisfying to hear the system fill up, pressurize, and hold tight without a single drop forming on your handiwork.

Remember, start small. Practice the heating and tinning technique on a piece of scrap copper pipe if you're nervous. Get a feel for how the solder flows when the metal is just the right temperature. That hands-on experience is worth more than any article.

So, the next time you see that dreaded drip, don't panic. Drain it down, grab your wire brush, and approach it with confidence. You've got this.

Leave A Comment