Comprehensive Guide to Fuel Pump Trucks: Your Key to Efficient Refueling

Advertisements

- January 1, 2026

Quick Navigation

- What Exactly Is a Fuel Pump Truck, and What Does It Do?

- Different Flavors: Types of Fuel Pump Trucks

- Buying Guide: What to Look For (Beyond the Price Tag)

- Keeping It Running: Maintenance is Not Optional

- Fuel Pump Truck FAQs: Answering Your Real Questions

- Safety First, Last, and Always

- The Future and Trends in Mobile Fueling

Let's talk about fuel pump trucks. You've probably seen them on construction sites, at farms, or parked near large equipment yards. They look like a regular truck, but with a big tank on the back and a hose reel. That's the basic picture. But there's so much more going on under the surface. If you're in the market for one, or if your job involves managing a fleet that relies on them, you know the decision isn't as simple as picking the shiniest one. Get it wrong, and you're looking at downtime, wasted money, and maybe even a safety headache. Get it right, and it's like having a reliable gas station that follows your equipment anywhere.

I remember visiting a large quarry operation a few years back. They had a fuel pump truck that was, frankly, a mess. The paint was peeling, the meter was foggy, and the driver mentioned "small" leaks that were "no big deal." That truck wasn't just an eyesore; it was a rolling liability. It broke down two weeks later, stranding three excavators and delaying a project by days. The cost of that downtime dwarfed the price of proper maintenance. That experience stuck with me. It's why I believe understanding these machines inside and out isn't just for mechanics—it's crucial for anyone whose business runs on diesel, gasoline, or even DEF fluid.

What Exactly Is a Fuel Pump Truck, and What Does It Do?

Think of it as a gas station on wheels. But instead of you driving to it, it drives to your bulldozer, generator, or combine harvester. The primary job of any fuel pump truck is safe storage, transport, and accurate dispensing. It's a critical link in the supply chain for industries where mobility is key.

You'll find these trucks serving a huge range of sectors. Construction is a big one—keeping cranes, backhoes, and rollers running without sending operators off-site for hours. Agriculture relies on them heavily during harvest season. Mining, forestry, municipalities (for fueling snow plows and utility trucks), airports (for ground support equipment), and even large event companies use them. The common thread? A need for efficient, on-demand fueling away from fixed infrastructure.

How does it work? It's a simple concept with complex engineering. A heavy-duty chassis carries a large, baffled tank (to prevent liquid sloshing). A powerful pump, usually powered by the truck's engine or a separate small engine, pulls fuel from the tank and pushes it through a filter, a meter for measurement, and out through a heavy-duty hose with a nozzle. The operator controls everything from a panel, often tracking the amount dispensed. Safety features are non-negotiable, from grounding reels to prevent static sparks to emergency shut-off switches.

Key Components You Can't Ignore

When you're evaluating a fuel pump truck, don't just kick the tires. Look at these parts closely. They make or break the machine's usefulness and lifespan.

- The Tank: This is the heart. Material matters—usually aluminum (lightweight, corrosion-resistant) or steel (durable, often less expensive). Capacity ranges from a modest 500 gallons to well over 5,000 gallons for massive operations. Look for internal baffles. A tank without proper baffles is dangerous; the fuel surge can destabilize the truck during transport.

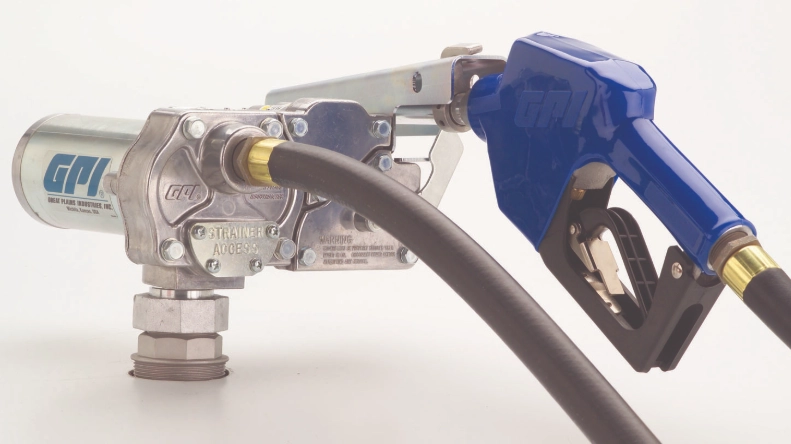

- The Pump: The muscle. You need enough flow rate (measured in gallons per minute, or GPM) to make refueling fast but not so powerful it's wasteful or hard to control. A 20-30 GPM pump is common for diesel applications. The type matters too—rotary gear pumps are workhorses for their durability and consistent flow.

- The Metering System: The brain and the accountant. This is how you track fuel usage, charge clients, or manage internal costs. A good mechanical or electronic meter needs to be certified for trade (like NTEP in the US) if you're selling fuel. Accuracy is paramount. A faulty meter is like a cash register that can't count.

- The Hose Reel and Nozzle: The arms. The hose needs to be long enough (often 50-100 feet) to reach equipment without repositioning the truck constantly. It must be rated for fuel and have proper reinforcement. The nozzle should be automatic shut-off to prevent overfills. I've seen cheap hoses crack and weep fuel—a fire hazard and an environmental risk.

- The Control Panel & Safety Gear: The nerve center. Look for clearly labeled switches, emergency stop buttons, and function indicators. Safety gear includes a fire extinguisher (mounted and accessible), spill containment kits, and a bonding/grounding reel. Never, ever skip on this stuff. The NFPA 385 standard for tank vehicles is a good place to start understanding the regulatory baseline.

So, you get the idea. It's a system. A weakness in one component can drag the whole operation down.

Different Flavors: Types of Fuel Pump Trucks

Not all fuel pump trucks are built the same. The right type depends entirely on your volume, frequency, terrain, and budget. Choosing the wrong style is a classic and expensive mistake.

| Type | Best For | Key Advantages | Potential Drawbacks |

|---|---|---|---|

| Truck-Mounted (Chassis Mount) | High-volume, daily use. Large construction sites, mining, large farms. | Highest capacity. Integrated design. Often most robust and feature-complete. | Highest upfront cost. Requires a dedicated truck and CDL driver in many cases. |

| Trailer-Mounted (Fuel Trailer) | Medium-volume, seasonal or multi-site use. Contractors, smaller farms, municipalities. | Flexibility. One tractor can tow different trailers. Lower initial cost than a dedicated truck. Can be parked and disconnected. | Requires a capable tow vehicle. Slightly more complex setup at each site. May have smaller capacity. |

| Skid-Mounted Units | Versatility. Can be loaded onto a flatbed truck, placed in a pickup bed, or set semi-permanently. | Maximum flexibility. Can be moved between different vehicles. Good for rental fleets or specialized applications. | Less streamlined for daily driving. May lack some integrated safety features of dedicated trucks. |

| Custom/Specialty Trucks | Unique applications. Aviation refueling (AVGAS/JET-A), DEF-only trucks, dual-product trucks (carrying diesel and gasoline). | Tailored to exact needs. Can handle specific, sensitive fuels with dedicated components. | Longer lead time. Significantly higher cost. Requires very specialized knowledge. |

I have a soft spot for a well-set-up trailer unit for smaller businesses. The cost savings are real, and the ability to use your existing heavy-duty pickup is a huge plus. But for non-stop, high-demand environments, the dedicated truck-mounted fuel pump truck is king. It's built for the punishment.

Buying Guide: What to Look For (Beyond the Price Tag)

Okay, so you know you need one. How do you pick the right fuel pump truck? Let's move past the sticker shock and talk about what actually matters for the long haul.

Capacity and Flow Rate: Matching Your Needs

Bigger isn't always better. A 3,000-gallon tank sounds impressive, but if you only use 500 gallons a day, you're carrying dead weight, stressing the chassis, and possibly letting fuel sit too long (which can lead to microbial growth). Calculate your average daily and weekly fuel consumption. Add a 20-30% buffer for busy periods, and that's a good target capacity.

Flow rate is about patience and efficiency. A 10 GPM pump will take 10 minutes to put 100 gallons in a tank. A 50 GPM pump will do it in 2 minutes. But the faster pump needs a bigger engine to drive it, costs more, and requires careful handling to avoid spills. For most diesel equipment refueling, a 20-35 GPM pump is the sweet spot. It's fast enough to not waste time but controlled enough for safe operation.

Chassis and Mobility

Where will this truck go? Paved roads only? Or muddy, rutted construction sites? The answer dictates everything from chassis type (4x2 vs. 4x4) to tire selection and ground clearance. A highway tractor won't last a week on a mining haul road. Also, consider licensing. In the US, a truck with a Gross Vehicle Weight Rating (GVWR) over 26,001 lbs typically requires a Commercial Driver's License (CDL) to operate. Sometimes, opting for a slightly smaller tank to stay under the CDL threshold can save huge headaches and driver qualification costs.

Safety and Compliance Features

This isn't the area to cut corners. Your fuel pump truck must comply with regulations from the Department of Transportation (DOT), the Environmental Protection Agency (EPA), and possibly state or local fire codes.

- Spill Containment: Look for secondary containment—a drip pan under the pump area, sealed compartments. It's for catching small drips before they hit the ground.

- Venting and Vapor Recovery: Modern systems are closed, capturing fumes instead of releasing them. This is better for the environment, for worker health, and often required by law.

- Emergency Shut-Offs: There should be multiple: one at the dispenser, one on the control panel, and a "deadman" switch on the nozzle itself that stops flow if dropped.

- Lighting and Marking: DOT requires specific placards (like flammable liquid diamonds), reflective tape, and proper lighting. It's not just about fines; it's about being visible and warning other drivers.

Resources like the Federal Motor Carrier Safety Administration (FMCSA) website have guides on regulations for tank vehicles. It's dry reading, but it's essential.

New vs. Used: The Eternal Debate

New gives you peace of mind: warranty, latest features, and no hidden history. Used can save 30-50% upfront. My take? If this truck is the core of your revenue-generating operation and downtime is catastrophic, lean new. If it's for supplemental or seasonal use, and you have a good mechanic, a well-vetted used fuel pump truck can be a brilliant value. Just budget immediately for a full fluid change, filter replacement, and hose inspection.

Let me be honest—I've been burned on a used truck purchase early in my career. The pump failed within a month, and the repair cost ate up all the "savings." The lesson? Factor in a thorough inspection by a third party as a non-negotiable cost of buying used.

Keeping It Running: Maintenance is Not Optional

A fuel pump truck is a precision fluid-handling system. Neglect it, and it will fail, often at the worst possible time. This isn't like ignoring an oil change on your sedan for a few extra miles.

Here's a basic maintenance checklist that should become habit:

- Daily/Pre-Use: Walk-around inspection. Look for leaks (wet spots, drips, fuel smell). Check hose condition for cracks or abrasions. Ensure grounding reel cable is intact and makes good contact. Check fluid levels (engine oil, coolant, not just fuel!).

- Weekly/Monthly: Test emergency shut-off functions. Inspect filters (both fuel and air). Clean the pump area and tank surfaces of dirt and grime. Check tire pressure and tread.

- Annually/Bi-Annually: This is the big one. Get the meter recalibrated and certified if used for commerce. Have a professional inspect the tank interior for corrosion or sludge buildup. Replace all filters and consider sending fuel samples for analysis to check for water or microbial contamination. Perform full chassis maintenance as per the truck manufacturer's schedule.

The biggest enemy of a fuel pump truck is water in the tank. Water promotes rust and creates the perfect environment for "diesel bugs"—microbes that live at the fuel/water interface. They create slime that clogs filters and damages injectors. Using a biocide treatment and keeping tanks full (to minimize condensation) are simple, effective practices.

Fuel Pump Truck FAQs: Answering Your Real Questions

Safety First, Last, and Always

We have to talk about this separately because it's that important. Operating a fuel pump truck involves flammable liquids under pressure. Complacency is the enemy.

Grounding and Bonding: This is the #1 rule to prevent static sparks. Before you open any tank or start pumping, you must connect the truck to the equipment being fueled using a dedicated grounding cable. This equalizes the electrical potential, so a static charge doesn't jump as a spark. I don't care how many times you've done it without incident—skip this step once, and you could be the incident.

Spill Response: Have a plan and a kit. The kit should include absorbent pads, socks (to contain spills), a container for used absorbents, and PPE. Know who to call for a significant spill (it's usually a state environmental agency). A small, contained spill cleaned up promptly is a minor issue. One that reaches a storm drain is a regulatory nightmare.

Driver Training: This isn't just "here's the start button." Drivers need training on safe operating procedures, emergency shutdown, basic troubleshooting, spill response, and the properties of the fuels they're handling. Document this training.

The Future and Trends in Mobile Fueling

The world of fuel pump trucks isn't static. It's evolving with technology and environmental pressures.

Telematics and IoT: This is huge. Modern trucks are getting sensors for everything: fuel level in real-time, pump run hours, GPS location, door/open access logs. This data streams to the cloud, allowing fleet managers to optimize routes, schedule maintenance predictively, and monitor usage remotely. It's moving from a "dumb" truck to a connected asset.

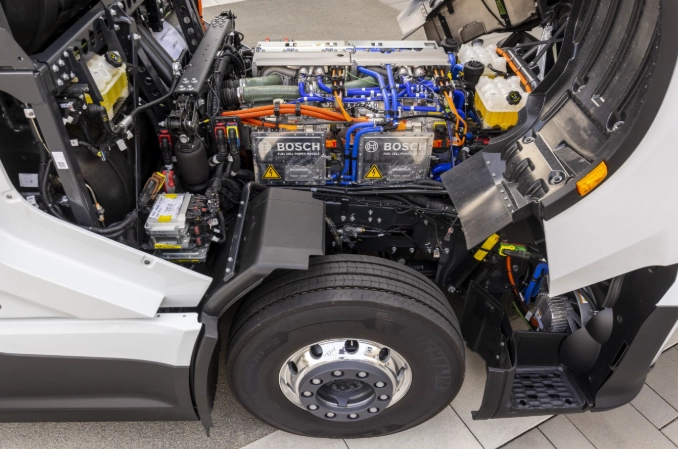

Alternative Fuel Compatibility: The rise of biodiesel blends, renewable diesel, and even plans for hydrogen or electric mobile refuelers. Some newer fuel pump trucks are being built with materials compatible with higher biodiesel blends (like B20) which can be more corrosive than standard diesel. Thinking about future fuel mandates is part of a smart purchase now.

Emission Controls: Truck chassis engines are getting cleaner (think EPA emissions standards), and the auxiliary engines that often power the pumps are following suit. Expect more electric-driven pumps (powered by the truck's alternator/battery system) to eliminate a separate gas engine's emissions and noise.

Industry associations like the Association of Equipment Manufacturers (AEM) often have insights and data on trends affecting mobile equipment, including fueling solutions.

Look, choosing and operating a fuel pump truck is a significant commitment. It's a major piece of capital equipment that plays a vital, behind-the-scenes role in keeping your primary assets—your excavators, tractors, generators—alive and working. Don't rush the decision. Define your needs precisely, prioritize safety and reliability over flashy extras, and commit to a rigorous maintenance routine.

A reliable fuel pump truck isn't an expense; it's a productivity engine. When it hums along quietly in the background, delivering fuel where and when it's needed, you barely notice it. And that's the sign of a great one. When it's constantly breaking down or causing worries, it becomes the center of your attention for all the wrong reasons. Do your homework, invest wisely, and treat it well. It'll pay you back for years.

Hope this deep dive helps you navigate the process with more confidence.

Leave A Comment