3 Types of Starter Motors (2024 Guide): How to Choose the Right One

Advertisements

- January 13, 2026

Quick Navigation Guide

- The Workhorse of the Past: Direct Drive Starters

- The Game Changer: Gear Reduction Starters

- The Modern Standard: Permanent Magnet Gear Reduction (PMGR) Starters

- Side-by-Side: Comparing the 3 Types of Starter Motor

- How Do You Know Which One You Have? (And Which to Buy)

- Common Problems Across All 3 Types

- Final Thoughts: It's Not Just a Black Box

You turn the key (or push the button), and there it is—that satisfying whirring and cranking sound that means your engine is coming to life. We take it for granted until the day it doesn't happen. Then, that silence is expensive. Most drivers know they have a starter, but very few have any clue about the different engineering that goes into them. I've lost count of how many times someone has brought in a starter for a rebuild, only for us to find they've been sold the completely wrong type for their vehicle. It's frustrating for everyone.

So let's clear that up. When we talk about the 3 types of starter motor in common use in vehicles today, we're really talking about three different solutions to the same basic problem: how to spin your engine fast enough to start it, using power from a relatively small 12-volt battery. The differences aren't just academic; they affect weight, cost, reliability, and what happens when you need a replacement. Knowing which one you have can save you a major headache down the road.

The core 3 types of starter motor designs you'll encounter are the Direct Drive (or Inertia) Starter, the Gear Reduction Starter, and the Permanent Magnet Gear Reduction (PMGR) Starter. Some folks might split hairs about sub-types, but for 95% of automotive applications, this is the trio that matters.

The Workhorse of the Past: Direct Drive Starters

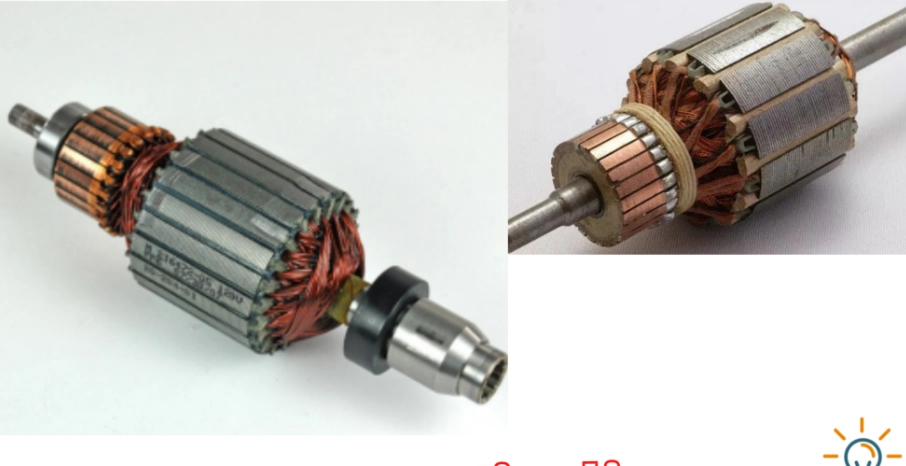

Let's start with the classic, the design that was under the hood of virtually every car for most of the 20th century. The direct drive starter is beautifully simple in concept. The electric motor's armature shaft is directly connected to the pinion gear (the little gear that engages with your engine's flywheel). There's a solenoid mounted on top that does two jobs: it slams the pinion gear forward into the flywheel, and it closes a massive set of contacts to send full battery power to the motor.

When you turn the key, here's the sequence: solenoid engages, pinion shoots out, contacts close, motor spins at full torque, engine cranks. The simplicity is its main virtue. Fewer parts can mean (in theory) fewer things to break. They also produce a very distinct sound—a slower, heavier *urrr-urrr-urrr* cranking sound compared to the faster whine of modern starters.

Where You'll Still Find Them & The Big Downsides

You'll mostly find these on classic cars, older agricultural equipment, and some motorcycles. I still rebuild them for vintage Mustang and Chevy owners. They have a certain nostalgic, mechanical charm.

But let's be honest about their flaws. They are heavy. All that copper winding and iron needed to generate enough torque directly results in a bulky unit. They also draw a lot of current—often 200 amps or more. This is hard on batteries and wiring. The worst part, in my experience, is the engagement mechanism. That violent slam of the pinion gear leads to worn teeth on both the pinion and the flywheel over time. I've seen more than a few where the pinion just bounces off without engaging, making a horrible grinding sound. Not great.

So, while robust in a way, the direct drive starter is largely a relic. It did the job for its time, but engineering moved on for good reasons. It's the first of our 3 types of starter motor, but for most people, it's one they'll only deal with in a restoration project.

The Game Changer: Gear Reduction Starters

This is where things got smart. Engineers asked a simple question: what if we don't try to get all the cranking torque directly from the motor? What if we use gears to multiply it? That's the core idea behind the gear reduction starter, and it revolutionized starter design.

Inside a gear reduction starter, the motor armature doesn't drive the pinion directly. Instead, it spins a small gear that meshes with a larger gear on a separate shaft, which then drives the pinion. This gearset—typically with a ratio between 2:1 and 4:1—reduces the speed but multiplies the torque. It's like using a low gear on a bicycle to climb a hill; you pedal slower, but with much more force.

This clever trick meant the motor itself could be smaller, lighter, and spin faster. A faster-spinning motor is more efficient and can be built with less copper and iron, saving weight and cost. The real-world benefit was massive: a gear reduction starter could be about 40-50% lighter than a direct drive unit for the same engine, while drawing less current and often cranking the engine faster.

The Two Flavors: Planetary and Spur Gear

There are two main ways to arrange those gears. The most common in automotive use is the planetary gear reduction. Imagine a small "sun" gear in the center, surrounded by several "planet" gears that rotate around it, all inside a ring gear. It's compact, robust, and handles high torque beautifully. This design is packed into a neat cylindrical package.

The other type uses a simple spur gear reduction—just two meshing gears offset from each other. This is often found on heavier-duty applications, like big diesel trucks. It's incredibly strong and serviceable, though a bit bulkier in shape.

The gear reduction starter was the second major step in the evolution of the 3 types of starter motor. It solved the weight and efficiency problems of the direct drive design. But engineers weren't done yet.

The Modern Standard: Permanent Magnet Gear Reduction (PMGR) Starters

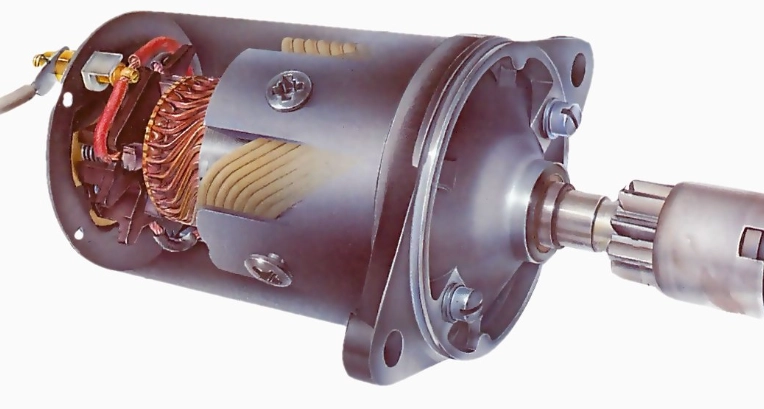

Take the genius of the gear reduction system and then make the motor itself even lighter and more efficient. How? Replace the heavy electromagnetic field coils (copper windings around iron poles) inside the motor with... strong permanent magnets. That's the PMGR starter.

This seems like such an obvious upgrade now. Those heavy copper windings are gone. The magnetic field is always present, provided by the magnets glued inside the motor housing. The result is a starter that is even lighter, more compact, and more energy-efficient than a traditional gear reduction model. It draws even less current from your battery, which is a huge benefit for modern cars packed with sensitive electronics.

Almost every gasoline-powered car and light truck built since the late 1990s uses a PMGR starter. They're the ubiquitous workhorse of the modern automotive world. You can identify them often by their compact, almost cylindrical shape and their surprisingly light weight when you lift one.

The Not-So-Secret Weakness

Nothing's perfect, right? The potential Achilles' heel of the PMGR starter is, ironically, those permanent magnets. They are typically made from a ceramic or rare-earth material and are bonded to the inside of the motor housing. Two things can kill them: extreme heat and physical impact.

I've seen it happen. A starter gets too hot (often from being located near exhaust headers), and the adhesive fails. A magnet comes loose, gets chewed up by the spinning armature, and the whole thing is instantly toast. Or, someone drops the starter on a concrete floor, and a magnet cracks. You can't really repair it; the whole motor housing usually needs to be replaced. This is why you sometimes hear mechanics grumble about the "disposability" of modern PMGR units compared to the rebuildable old-style starters.

Despite this, their benefits far outweigh the drawbacks for most applications. The PMGR starter represents the final (for now) and most refined member of the 3 types of starter motor family. It's a masterpiece of packaging and efficiency.

Side-by-Side: Comparing the 3 Types of Starter Motor

It's one thing to talk about them separately, but how do they really stack up against each other? This table lays it out plainly. It's the kind of comparison I wish more parts store employees had behind the counter.

| Feature | Direct Drive (Inertia) | Gear Reduction (Traditional) | Permanent Magnet Gear Reduction (PMGR) |

|---|---|---|---|

| Core Principle | Motor armature drives pinion directly. | Motor drives pinion via a gearset (planetary or spur) to multiply torque. | Gear reduction + permanent magnets replace field coils for lighter weight. |

| Weight & Size | Heaviest and bulkiest. | Lighter and more compact than direct drive. | Lightest and most compact of the three. |

| Current Draw | Very High (200+ Amps common) | Moderate to High | Lowest (more battery-friendly) |

| Cranking Speed | Slower, heavier cranking | Faster cranking due to higher motor RPM | Very fast, efficient cranking |

| Durability Concerns | Worn engagement gears, heavy solenoid contacts. | Gearset wear, solenoid failure. | Permanent magnets can detach or crack from heat/impact. |

| Repairability | Very high. Simple, robust parts. | High. Gears and solenoids often replaceable. | Lower. Magnet failure often requires housing replacement. |

| Typical Era & Use | Pre-1990s cars, classics, some equipment. | 1980s-1990s vehicles, heavy-duty diesel applications. | 1990s to present, most cars & light trucks. |

| Cost (for replacement) | Often higher due to lower volume/specialty. | Moderate, widely available for applicable models. | Generally the most affordable (high volume). |

Looking at that table, the evolution is clear. We moved from heavy, power-hungry, but simple units to light, efficient, and complex ones. The trade-off is often in the ease of repair. The old ones were meant to be fixed; many new ones are meant to be replaced as a unit. That's just the reality of modern manufacturing.

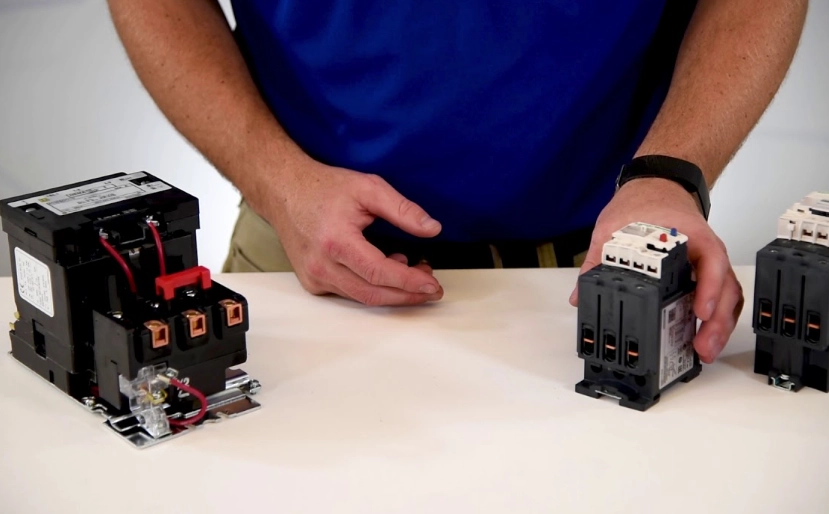

How Do You Know Which One You Have? (And Which to Buy)

This is the million-dollar question when your starter dies. You can't just guess. Putting the wrong type in can lead to poor cranking, damaged flywheels, or it simply not fitting.

First, use your vehicle information. The absolute best way is to look up the correct part for your specific Vehicle Identification Number (VIN). Any reputable parts store website or catalog will do this. Your car's manufacturer designed it for one of the 3 types of starter motor, so stick with that design.

Second, look at the old one. If you have it out, you can often tell:

- Direct Drive: Large, heavy, often with a long cylindrical body and a separate solenoid bolted prominently on top.

- Gear Reduction (non-PM): Lighter, often has a more "offset" or bulky shape if it's a spur gear type, or a cylindrical shape with a noticeable "bulge" for the planetary gearset.

- PMGR: Compact, lightweight, almost always cylindrical and smooth. Often has a smaller integrated solenoid. If you see "PMGR" or "Permanent Magnet" stamped on it, that's a dead giveaway.

My personal rule? For a daily driver, always replace with the exact OEM-specified type. The engineers got it right. For a project or classic car, upgrading to a modern gear reduction or PMGR starter is one of the best bang-for-your-buck reliability upgrades you can make.

Common Problems Across All 3 Types

While the internal designs differ, many failure symptoms are similar because they share common systems. Let's cut through the noise.

The Single Click (No Cranking): This is almost always a solenoid or high-current connection issue. The solenoid clicks (you hear it), but it fails to close the main contacts to send power to the motor, or the motor's ground/power connection is broken. It's rarely the motor itself seizing. Check battery cables, the connection at the starter, and the solenoid.

Grinding Noise: This is a meshing problem. The pinion gear isn't engaging the flywheel properly. Causes: worn teeth on the starter pinion or engine flywheel, a weak solenoid that doesn't throw the pinion all the way, or (on direct drive starters) a faulty engagement mechanism. A grinding starter will quickly destroy both gears.

Whirring/Spinning Sound (No Engine Turn): The starter motor spins, but the pinion isn't engaging the flywheel at all. On direct drive starters, this is often a broken engagement mechanism. On gear reduction types, it can be a completely stripped gearset in the reduction unit. The pinion just sits still while the motor whines away.

Slow, Lazy Crank: Usually a power supply issue, not a starter type issue. Weak battery, corroded cables, or poor grounds. However, a starter with worn bushings or beginning to short internally can also draw excessive current and crank slowly.

Final Thoughts: It's Not Just a Black Box

Hopefully, by now, that mysterious component on the side of your engine isn't so mysterious. Understanding the 3 types of starter motor—direct drive, gear reduction, and permanent magnet gear reduction—gives you a real advantage. It helps you diagnose problems better, buy the correct part with confidence, and even make smart upgrade decisions for older vehicles.

The trend is clear: lighter, smarter, more efficient. The direct drive starter is a testament to robust, simple engineering. The gear reduction starter introduced clever mechanical advantage. The PMGR starter perfected the package with modern materials. Each has its place, its strengths, and its characteristic failures.

Next time you hear that starter crank, you'll know a bit more about the little engineering marvel making it happen. And if it ever fails, you won't be in the dark. You'll know what questions to ask, what to look for, and how to make sure you get the right part to get back on the road. That's the real goal here—turning a moment of panic into a manageable repair.

Drive safe.

Leave A Comment